The Releated Products of Customized Diamond Wire Saw For Concrete

Customized Diamond Wire Saw For Concrete

Table of Contents

Customized Diamond Wire Saw for Concrete: Precision Cutting

In the world of construction and demolition, precision is key. When it comes to cutting through thick slabs of concrete, a customized diamond wire saw stands out as a superior solution. This specialized tool offers unparalleled accuracy, speed, and efficiency, making it indispensable for projects where traditional methods fall short. Let’s delve into how this technology enhances cutting operations.

Benefits of Using a Customized Diamond Wire Saw for Concrete

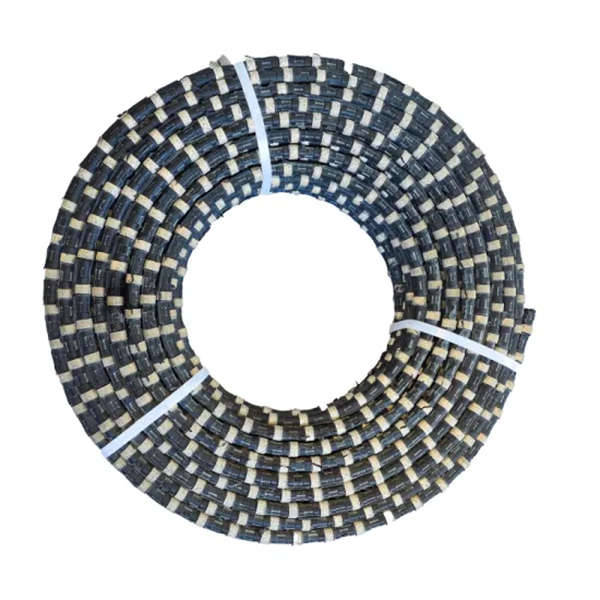

The primary benefit of using a customized diamond wire saw for concrete is its ability to cut through dense materials with minimal effort. The saw’s design incorporates a thin, flexible wire embedded with diamond grains, which provides a clean, precise cut every time. Unlike conventional saws, these tools can operate in tight spaces, reducing the need for additional equipment or manpower. Additionally, they produce less noise and dust, creating a safer work environment.

Applications of Customized Diamond Wire Saws for Concrete

From bridge demolition to the removal of foundations, customized diamond wire saws find applications across various sectors. They are particularly useful in situations requiring controlled demolition, where preserving the structural integrity of surrounding areas is crucial. Whether cutting through reinforced concrete or other hard materials, these saws offer the flexibility and power needed to get the job done right.

How Customized Diamond Wire Saws for Concrete Work

Understanding the mechanics behind customized diamond wire saws sheds light on their effectiveness. These saws use a looped wire coated with industrial diamonds that rotates at high speeds, slicing through concrete effortlessly. The continuous motion ensures smooth, straight cuts without the risk of overheating or damaging the material being cut. Moreover, the system can be adjusted based on the thickness and hardness of the concrete, making it versatile enough to handle different tasks.

Selecting the Right Customized Diamond Wire Saw for Concrete Projects

Choosing the appropriate diamond wire saw for your project involves considering several factors. First, assess the size and nature of the job, as well as any specific requirements regarding noise levels or debris management. Next, evaluate the power source and whether the saw needs to be portable. Consulting with experts who specialize in concrete cutting equipment can provide valuable insights into selecting a model that best suits your needs.

Maintenance and Care of Customized Diamond Wire Saws for Concrete

Proper maintenance is essential for extending the lifespan of your diamond wire saw and maintaining optimal performance. Regularly inspect the wire for wear and tear, and replace it when necessary to prevent accidents. Keep the machine clean and lubricated, following the manufacturer’s guidelines for care. By investing time in upkeep, you ensure that your saw remains a reliable asset for years to come.

Innovations in Customized Diamond Wire Saws for Concrete

As technology advances, so do the capabilities of diamond wire saws. Newer models incorporate features like improved diamond grit compositions and enhanced motor designs, boosting cutting speed and efficiency. Some even integrate smart systems that monitor operational parameters in real-time, alerting operators to potential issues before they become serious problems. Staying informed about these advancements allows professionals to leverage the latest tools effectively, driving productivity and innovation within the industry.

Request for Quotation

报错: 未找到这个表单