The Releated Products of Concrete Cutting Diamond Wire Saw

Concrete Cutting Diamond Wire Saw

Table of Contents

Understanding Concrete Cutting Diamond Wire Saws

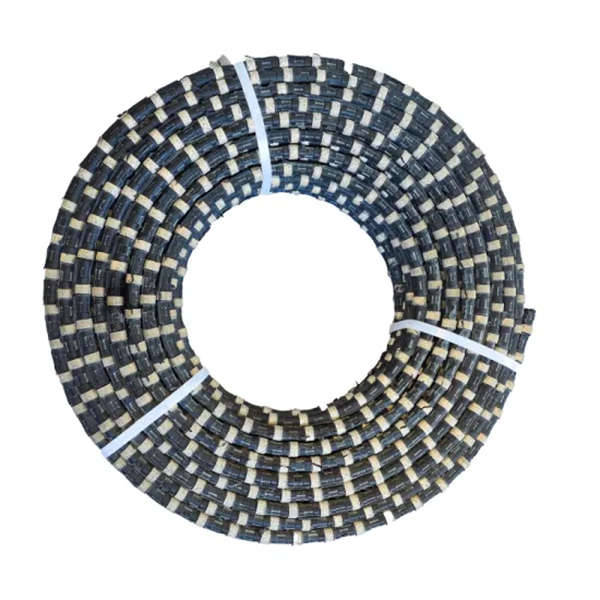

Concrete cutting diamond wire saws represent a significant advancement in the field of construction and demolition. These specialized tools have revolutionized how we approach cutting through dense, reinforced concrete structures. By using a thin, flexible wire embedded with diamond grains, these saws can slice through materials with precision and efficiency that traditional methods simply cannot match.

Diamond Wire Saw: Precision in Concrete Cutting

Precision is paramount when it comes to concrete cutting. The diamond wire saw offers unparalleled accuracy due to its design. Unlike traditional blade-based saws, which can sometimes struggle with straightness over long cuts or in tight spaces, the diamond wire saw excels. Its ability to make precise cuts without chipping or cracking the surrounding material makes it ideal for intricate work, such as cutting out sections of bridge decks or creating openings in walls.

Benefits of Using a Diamond Wire Saw for Concrete Cutting

The benefits of using a diamond wire saw extend far beyond just precision. One key advantage is the reduced noise level compared to other cutting methods. This makes it particularly suitable for projects located in residential areas or during hours when noise restrictions apply. Additionally, because the wire can be guided around obstacles, it provides greater flexibility in terms of where and how cuts can be made, leading to increased productivity on job sites.

How Does a Concrete Cutting Diamond Wire Saw Work?

Understanding the mechanics of a diamond wire saw is essential for maximizing its potential. Essentially, the process involves a continuous loop of steel cable embedded with industrial diamonds. When the wire is tensioned and moved at high speeds, these diamonds grind away at the concrete, effectively cutting through it. Water is typically used during this process to cool the wire and suppress dust, ensuring a cleaner working environment.

Applications of Diamond Wire Saws in Concrete Cutting

From small-scale renovation projects to large-scale infrastructure developments, the applications of diamond wire saws in concrete cutting are vast. They are commonly used in bridge and highway construction, where they can cut through old concrete to make way for new structures. In building renovations, they help create new openings or remove sections of floor or wall with minimal disruption to the surrounding area. Their versatility also extends to the mining industry, where they are used for cutting stone and other hard materials.

Maintenance Tips for Concrete Cutting Diamond Wire Saws

To ensure optimal performance and longevity, proper maintenance of your diamond wire saw is crucial. Regular inspections should be conducted to check for any signs of wear or damage to the wire and guide wheels. Keeping the system clean and free from debris is important, as is ensuring that all moving parts are properly lubricated. Following the manufacturer’s guidelines for use and maintenance will help maintain the saw’s cutting efficiency and prolong its service life.

Choosing the Right Diamond Wire Saw for Your Concrete Cutting Needs

Selecting the appropriate diamond wire saw depends on several factors, including the size and type of project, the material being cut, and budget constraints. For larger jobs requiring heavy-duty equipment, industrial-grade models are necessary. Smaller, more portable units might suffice for residential or light commercial applications. Consulting with a specialist in concrete cutting tools can provide valuable insights into choosing the best option for specific needs.

Request for Quotation

报错: 未找到这个表单