The Releated Products of Cnc Stone Cutting Machine

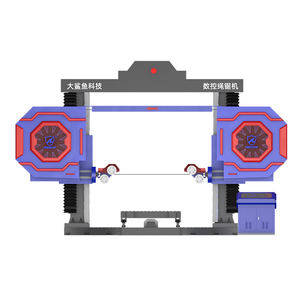

Cnc Stone Cutting Machine

CNC Stone Cutting Machine: Precision, Efficiency, and Innovation

In the realm of stone fabrication, precision and efficiency are paramount. This is where CNC stone cutting machines come into play, revolutionizing the industry with their unparalleled accuracy and speed. Whether you’re dealing with granite, marble, or quartz, these machines ensure that every cut is made to perfection. In this article, we will explore how CNC stone cutting machines are changing the landscape of stone processing.

CNC Stone Cutting Machine: Enhancing Precision

One of the most significant advantages of using a CNC stone cutting machine is its ability to enhance precision. Traditional methods often relied on human skill and could result in inconsistencies. With advanced software and robotic arms, CNC machines can cut stones with micron-level accuracy, ensuring that every piece matches the design specifications perfectly. This level of precision is crucial for creating intricate designs and complex shapes that would be difficult, if not impossible, to achieve manually.

Advantages of CNC Stone Cutting Machines in Efficiency

Efficiency is another key benefit offered by CNC stone cutting machines. These devices can work continuously without the need for breaks, significantly increasing production rates compared to manual operations. Moreover, they reduce material waste by optimizing the layout of cuts, which means more stone is used effectively. The result? Higher productivity and lower costs over time, making them a smart investment for any stone fabrication business.

How CNC Stone Cutting Machines Work

Understanding how CNC stone cutting machines operate provides insight into why they are so effective. The process begins with creating a digital design file that specifies the exact dimensions and shape required. This file is then fed into the CNC machine’s control system, which translates the design into precise movements for the cutting tool. Using water jets or diamond blades, the machine cuts through the stone with incredible speed and accuracy, guided by the pre-programmed instructions.

Maintenance and Operation of CNC Stone Cutting Machines

To keep your CNC stone cutting machine running smoothly, regular maintenance is essential. This includes cleaning the machine, lubricating moving parts, and checking for wear and tear on components like the cutting tools. Operators must also receive proper training to use the machine safely and efficiently. Many manufacturers offer comprehensive training programs and support services to help businesses get the most out of their investment.

Environmental Impact of Using CNC Stone Cutting Machines

It’s important to consider the environmental impact of any manufacturing process. Compared to traditional stone cutting methods, CNC stone cutting machines generally produce less noise pollution and dust. Additionally, because they optimize material usage, there’s less waste generated during the cutting process. By choosing energy-efficient models and implementing sustainable practices, businesses can further minimize their ecological footprint while enjoying the benefits of advanced technology.

Future Innovations in CNC Stone Cutting Technology

As technology continues to evolve, so too does the potential of CNC stone cutting machines. Innovations such as artificial intelligence (AI) and machine learning algorithms promise to make these devices even smarter and more adaptable. AI can analyze data from past projects to improve cutting strategies, while machine learning allows machines to adjust their performance based on real-time feedback. These developments suggest a future where CNC stone cutting machines will become increasingly versatile and indispensable in the world of stone fabrication.

By embracing CNC stone cutting machines, businesses can achieve new levels of precision, efficiency, and innovation in their operations. As the technology advances, it opens up exciting possibilities for creating beautiful, functional stonework with unparalleled quality and consistency.

Request for Quotation

报错: 未找到这个表单