The Releated Products of Cnc Diamond Wire Saw Cutting Machine

Cnc Diamond Wire Saw Cutting Machine

CNC Diamond Wire Saw Cutting Machine: Precision in Every Cut

In the realm of industrial cutting, precision and efficiency are paramount. The CNC Diamond Wire Saw Cutting Machine stands out as a revolutionary tool designed to meet these demands. This article explores the technology behind these machines, their applications, benefits, and how they continue to shape the future of material processing.

CNC Diamond Wire Saw Cutting Machine: An Overview

The CNC Diamond Wire Saw Cutting Machine is a sophisticated piece of equipment that combines computer numerical control (CNC) technology with diamond wire sawing techniques. This combination allows for precise, clean cuts on a variety of materials including metals, stone, and composites. The use of diamond-coated wires ensures durability and longevity, making it ideal for continuous operations in demanding environments.

Advantages of Using CNC Diamond Wire Saw Cutting Machines

One of the key advantages of using a CNC Diamond Wire Saw Cutting Machine is its ability to achieve high accuracy and repeatability. With minimal operator intervention required, these machines can work around the clock, significantly increasing productivity. Additionally, they offer:

– Reduced material waste

– Enhanced safety features

– Versatility in handling different materials

These benefits make them indispensable in industries such as construction, manufacturing, and even in specialized areas like gemstone cutting.

Applications of CNC Diamond Wire Saw Cutting Machines

The versatility of CNC Diamond Wire Saw Cutting Machines makes them suitable for a wide range of applications. They are commonly used in:

– Cutting and shaping marble and granite slabs

– Processing solar silicon wafers

– Fabricating intricate metal parts

In each application, the CNC Diamond Wire Saw Cutting Machine demonstrates its superior cutting capabilities, contributing to higher quality products and more efficient production processes.

How CNC Diamond Wire Saw Cutting Machines Work

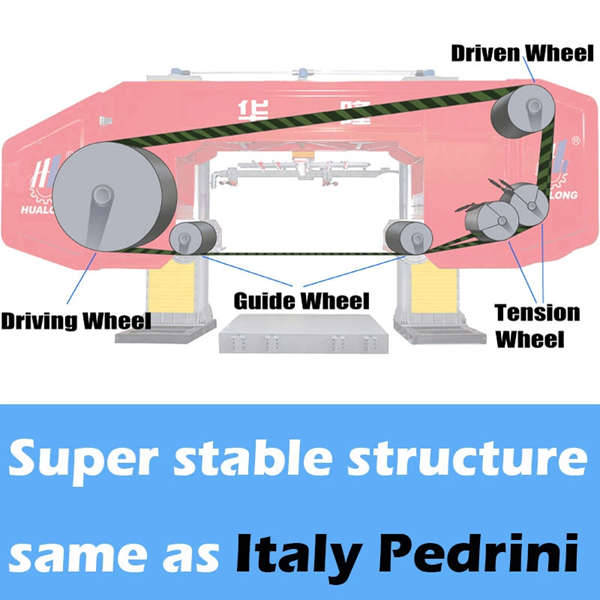

Understanding how a CNC Diamond Wire Saw Cutting Machine operates provides insight into its effectiveness. The process involves a thin, flexible wire embedded with diamond particles that rotates at high speeds. Controlled by CNC programming, this wire moves through the material along predetermined paths, ensuring precise cuts every time.

Advanced software enables complex designs to be programmed easily, allowing for customization and flexibility in production runs. This level of control is particularly beneficial when working with delicate or expensive materials where precision is critical.

Maintenance and Care of CNC Diamond Wire Saw Cutting Machines

To ensure optimal performance and longevity of your CNC Diamond Wire Saw Cutting Machine, regular maintenance is essential. Key aspects include:

– Checking and replacing worn wires

– Lubricating moving parts

– Cleaning the machine to remove debris

Proper care not only extends the life of the machine but also maintains its cutting efficiency and accuracy. Manufacturers often provide detailed guidelines on recommended maintenance schedules and procedures.

Future Prospects of CNC Diamond Wire Saw Technology

As technology continues to evolve, so too does the potential of CNC Diamond Wire Saw Cutting Machines. Innovations in material science and automation are likely to lead to further improvements in speed, accuracy, and adaptability. These advancements promise to open up new possibilities in material processing, pushing the boundaries of what is currently achievable.

By investing in a CNC Diamond Wire Saw Cutting Machine, businesses can position themselves at the forefront of technological innovation, ready to meet the challenges of tomorrow’s manufacturing landscape.

Request for Quotation

报错: 未找到这个表单