The Releated Products of Ceramic Tile Wet Saw Or Dry

Ceramic Tile Wet Saw Or Dry

Table of Contents

Choosing Between Ceramic Tile Wet Saw or Dry Cutting Methods

When it comes to cutting ceramic tiles, professionals and DIY enthusiasts often face the decision between using a wet saw or opting for dry cutting methods. Each approach has its own set of advantages and considerations, making the choice dependent on specific project requirements, safety concerns, and personal preference. In this article, we will explore both ceramic tile wet saw and dry cutting techniques, providing insights into their benefits, drawbacks, and applications.

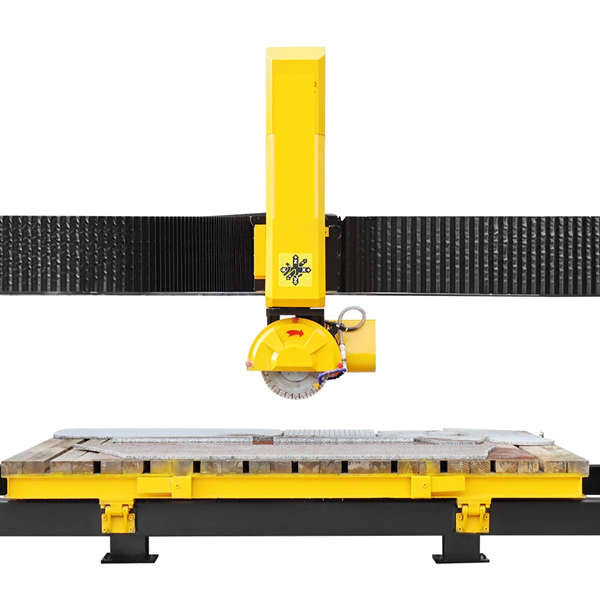

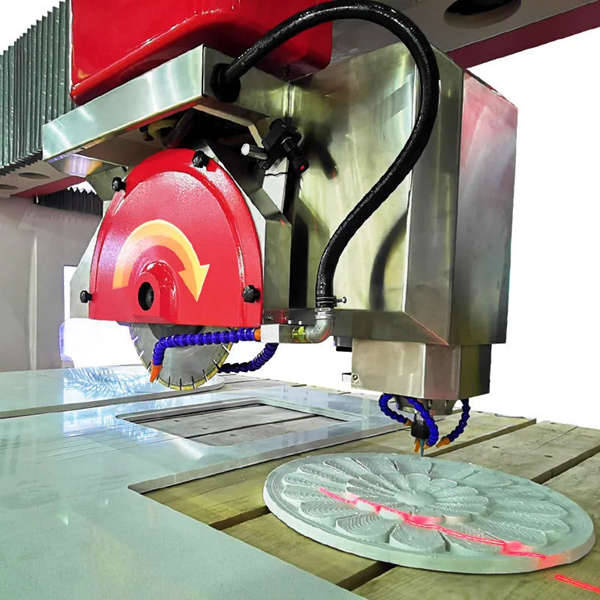

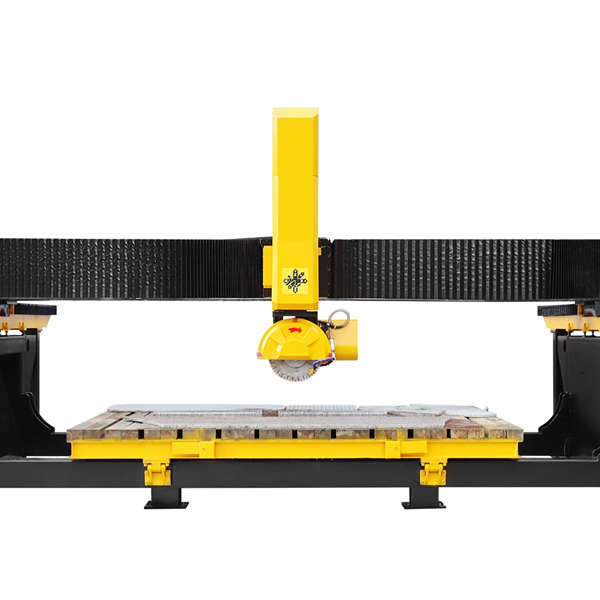

Ceramic Tile Wet Saw: Precision and Dust Reduction

Ceramic tile wet saws are a popular choice among professionals for their ability to provide precise cuts while minimizing dust. These saws use water continuously to cool the blade and reduce friction, ensuring smoother edges and cleaner cuts. The water also helps in managing the amount of dust generated during the cutting process, which is particularly beneficial in indoor environments where airborne particles can be a health hazard. Additionally, the cooling effect extends the life of the blade, making it a cost-effective option over time.

Dry Cutting Ceramic Tiles: Mobility and Convenience

On the other hand, dry cutting offers greater mobility and convenience compared to wet saws. This method does not require a constant water supply, making it ideal for outdoor projects or situations where access to water is limited. Dry cutting tools, such as diamond blades designed for dry use, can be used with handheld power tools, providing more flexibility and ease of use. However, it’s important to wear appropriate protective gear, including dust masks and goggles, due to the higher levels of dust produced.

Comparing Noise Levels: Ceramic Tile Wet Saw vs Dry Cutting

Noise pollution is another factor to consider when choosing between a ceramic tile wet saw or dry cutting. Generally, wet saws tend to produce less noise because the water helps dampen sound vibrations. Conversely, dry cutting can be significantly louder, especially when using handheld tools. For projects in residential areas or close to occupied spaces, the quieter operation of a wet saw might be preferred to minimize disturbance.

Safety Considerations for Ceramic Tile Wet Saw and Dry Cutting

Safety should always be a top priority when working with any power tool. Both wet and dry cutting methods come with their own set of precautions. For instance, while a ceramic tile wet saw reduces dust, it increases the risk of electrical hazards if proper precautions aren’t taken. Similarly, dry cutting requires diligent use of respiratory protection to avoid inhaling harmful silica dust. Always follow manufacturer guidelines and best practices to ensure a safe working environment.

Maintenance Requirements of Ceramic Tile Wet Saws

Regular maintenance is crucial for keeping your ceramic tile wet saw in optimal condition. This includes cleaning the water pump and tank regularly to prevent clogging, checking the blade alignment, and replacing worn parts. Although dry cutting tools may seem less demanding in terms of upkeep, they still require periodic inspection and replacement as needed to maintain efficiency and prolong the lifespan of the equipment.

Environmental Impact of Ceramic Tile Wet Saw and Dry Cutting

Lastly, environmental considerations play a role in the decision-making process. While wet saws help control dust, they do consume water, which could be a concern in regions facing water scarcity. On the flip side, dry cutting contributes to air pollution through particulate matter. Evaluating these impacts alongside other factors like project scope and location can guide you towards a more sustainable choice.

In conclusion, whether you opt for a ceramic tile wet saw or dry cutting depends largely on your specific needs and circumstances. Understanding the unique characteristics of each method equips you with the knowledge to make an informed decision that balances efficiency, safety, and sustainability.

Request for Quotation

报错: 未找到这个表单