The Releated Products of Bridge Saws For The Processing Of Ceramic

Bridge Saws For The Processing Of Ceramic

Understanding Bridge Saws for the Processing of Ceramic

In the dynamic world of ceramics processing, precision and efficiency are paramount. Bridge saws have emerged as indispensable tools, offering unparalleled accuracy and speed in cutting ceramic materials. Whether it’s for large-scale industrial applications or intricate design work, these machines play a crucial role. This article delves into the intricacies of bridge saws, exploring their capabilities, benefits, and how they revolutionize ceramic processing.

Types of Bridge Saws for Ceramic Processing

Bridge saws designed specifically for ceramics come in various models tailored to meet different needs. Some common types include manual, semi-automatic, and fully automatic systems. Each type has its unique set of features, making them suitable for specific tasks within the ceramic industry. Manual bridge saws provide basic functionality ideal for small-scale operations, while automated versions offer enhanced productivity through faster cutting speeds and reduced labor requirements.

Key Features of Bridge Saws for Ceramic Processing

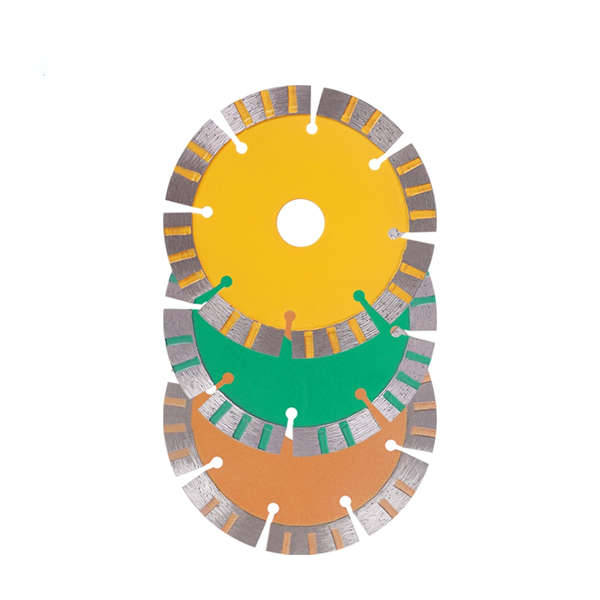

To ensure optimal performance when working with ceramics, bridge saws are equipped with several key features. High-powered motors combined with diamond blades enable clean, precise cuts through even the hardest ceramic materials. Additionally, advanced water cooling systems prevent overheating during prolonged use, maintaining blade integrity and prolonging its lifespan. Adjustable cutting heads allow operators to perform complex angles and bevel cuts with ease, enhancing versatility.

Benefits of Using Bridge Saws in Ceramic Processing

The adoption of bridge saws in ceramic processing brings numerous advantages over traditional methods. Foremost among these is increased productivity due to faster cutting times compared to handheld tools. Enhanced safety measures such as enclosed guards and emergency stop buttons significantly reduce workplace accidents. Furthermore, the ability to achieve consistent quality across multiple pieces makes bridge saws particularly valuable for batch production of ceramic tiles or slabs.

Maintenance and Safety Considerations for Bridge Saws Used in Ceramic Processing

Proper maintenance is essential for keeping your bridge saw in top condition. Regular cleaning of all components, especially the track system, ensures smooth operation and extends machine life. Lubrication of moving parts helps prevent wear and tear, while frequent inspections can catch potential issues before they become major problems. When operating a bridge saw, always adhere to established safety protocols. Wear appropriate personal protective equipment (PPE), including eye protection and dust masks, to safeguard against flying debris and harmful dust particles.

Applications of Bridge Saws in the Ceramic Industry

From manufacturing facilities to artisan workshops, bridge saws find diverse applications throughout the ceramic sector. In factories, these machines streamline the production process by enabling rapid, accurate cutting of raw materials into finished products. For artisans and designers, bridge saws facilitate creative freedom, allowing for the creation of intricate patterns and shapes not possible with conventional tools. Their adaptability makes them equally useful for both straight-line and curved cuts, broadening their appeal across the industry.

Future Trends in Bridge Saw Technology for Ceramic Processing

As technology continues to evolve, so too does the design and functionality of bridge saws used in ceramic processing. Innovations like CNC (Computer Numerical Control) integration promise even greater levels of automation and precision. These advancements not only improve efficiency but also open up new possibilities for customization and complexity in ceramic designs. As research and development efforts progress, we can expect future generations of bridge saws to further enhance the capabilities and competitiveness of the ceramic industry.

Request for Quotation

报错: 未找到这个表单