The Releated Products of Bridge Saw Ceramic

Bridge Saw Ceramic

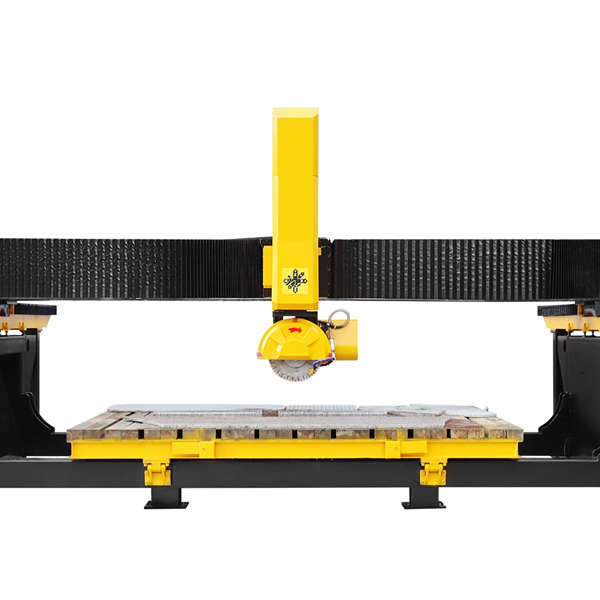

Understanding Bridge Saw Ceramic: Precision in Cutting Technology

In the world of manufacturing and construction, precision cutting tools are indispensable for achieving high-quality results. Among these tools, bridge saw ceramic has emerged as a game-changer, offering unparalleled accuracy and efficiency. This article delves into the intricacies of bridge saws designed specifically for ceramic materials, exploring their benefits, applications, and how they are revolutionizing industries.

Bridge Saw Ceramic: An Introduction to Advanced Cutting Solutions

Bridge saw ceramic machines are specialized pieces of equipment used primarily for cutting ceramic tiles, slabs, and other similar materials. These saws feature a sturdy frame, a large cutting bed, and a powerful motor that drives a diamond blade. The design allows for straight, precise cuts, making them ideal for both small-scale projects and large-scale industrial operations.

Advantages of Using Bridge Saw Ceramic in Modern Manufacturing

The adoption of bridge saw ceramic technology brings numerous advantages to manufacturers and construction professionals alike. Firstly, these saws offer exceptional precision, ensuring that every cut is accurate to within a fraction of a millimeter. Additionally, they are highly efficient, capable of processing materials quickly without compromising on quality. Safety features such as automatic shut-offs and dust collection systems further enhance their appeal, creating a safer working environment.

Applications of Bridge Saw Ceramic Across Industries

From small workshops to large factories, the application of bridge saw ceramic spans multiple sectors. In the construction industry, these saws are essential for fabricating custom countertops, flooring, and wall tiles from ceramic materials. Similarly, in the manufacturing sector, they play a crucial role in producing components for various products, including electronics and automotive parts. The versatility of bridge saw ceramic makes it a valuable asset across diverse industries.

Key Features of High-Quality Bridge Saw Ceramic Equipment

When selecting bridge saw ceramic machinery, several key features should be considered to ensure optimal performance and longevity. A robust frame constructed from durable materials like steel or aluminum provides stability during operation. Adjustable cutting heads allow for flexibility in handling different thicknesses of material, while digital controls enable precise adjustments for complex cuts. Efficient dust extraction systems not only improve air quality but also help maintain visibility around the workspace.

Maintenance Tips for Extending the Life of Your Bridge Saw Ceramic

Proper maintenance is critical for keeping your bridge saw ceramic running smoothly and extending its lifespan. Regular cleaning of the machine, especially the cutting area and tracks, prevents buildup that can affect accuracy. Lubricating moving parts helps reduce wear and tear, while inspecting and replacing worn blades ensures continued efficiency. Following manufacturer guidelines for maintenance schedules and using recommended parts and accessories will keep your bridge saw ceramic performing at its best.

The Future of Bridge Saw Ceramic Technology

As technology continues to advance, so too does the design and functionality of bridge saw ceramic. Innovations such as integrated laser guides for enhanced precision, more powerful motors for increased cutting speed, and smart control systems that optimize performance based on material type are becoming increasingly common. These advancements promise to make future models even more versatile and user-friendly, setting new standards in the world of precision cutting.

Bridge saw ceramic represents a significant leap forward in the capabilities of cutting equipment, offering unparalleled precision, efficiency, and versatility. Whether you’re a professional contractor looking to streamline your workflow or a manufacturer seeking to improve product quality, investing in this technology can provide substantial benefits. As we move forward, continued innovation will likely bring even more advanced features to market, further solidifying the position of bridge saw ceramic as a cornerstone of modern manufacturing and construction practices.

Request for Quotation

报错: 未找到这个表单