The Releated Products of Brazed Diamond Wire Saw

Brazed Diamond Wire Saw

Table of Contents

Understanding the Basics of Brazed Diamond Wire Saws

In the realm of precision cutting, especially within the construction and mining industries, the use of diamond tools has become indispensable. Among these, brazed diamond wire saws stand out for their efficiency and versatility. This article aims to explore the core components, applications, and benefits of brazed diamond wire saws, providing a comprehensive overview of this essential tool.

Brazed Diamond Wire Saw: An Overview

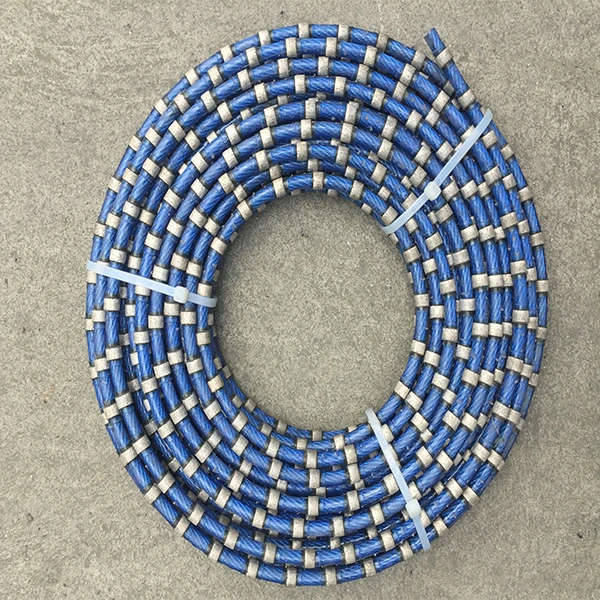

A brazed diamond wire saw consists of a thin metal wire, typically made from steel or similar durable materials, embedded with diamond particles. These particles are permanently bonded to the wire through a brazing process, which involves heating the wire and diamond segments until they fuse together. This creates a robust, continuous cutting edge capable of slicing through hard materials like stone, concrete, and even metals with remarkable ease.

Key Components of a Brazed Diamond Wire Saw

Understanding the key components of a brazed diamond wire saw is crucial for its effective operation and maintenance. The primary elements include:

– Wire Core: Made from high-strength steel, it provides the backbone of the saw.

– Diamond Segments: These are the cutting edges that are brazed onto the wire core. They come in various sizes and configurations depending on the material being cut.

– Guide Wheels: These help keep the wire aligned during cutting operations, ensuring accuracy and reducing wear.

Applications of Brazed Diamond Wire Saws

The versatility of brazed diamond wire saws makes them suitable for a wide range of applications across different sectors. Some common uses include:

– Construction: For precise cutting of concrete structures during demolition or renovation projects.

– Mining: In quarries, where they are used to extract blocks of stone or minerals with minimal waste.

– Manufacturing: Cutting large slabs of marble, granite, or other natural stones into smaller pieces for commercial use.

Benefits of Using Brazed Diamond Wire Saws

Compared to traditional cutting methods, brazed diamond wire saws offer several advantages:

– Increased Efficiency: They can cut faster and more accurately than conventional saws, leading to higher productivity.

– Reduced Material Loss: Due to the thinness of the wire, there is less material wasted as sawdust or debris.

– Flexibility: Suitable for both straight and curved cuts, making them ideal for complex projects.

Maintenance Tips for Brazed Diamond Wire Saws

To ensure optimal performance and longevity, regular maintenance is essential. Important steps include:

– Cleaning: After each use, clean the wire to remove any debris or residue.

– Inspection: Regularly check for signs of wear such as fraying or loose diamonds.

– Storage: Store the saw in a dry place when not in use to prevent rusting and damage.

Future Innovations in Brazed Diamond Wire Saws

As technology advances, so too does the design and functionality of brazed diamond wire saws. Future developments may include:

– Enhanced Durability: New materials and bonding techniques could further increase the lifespan of these tools.

– Automation: Integration with robotic systems for more precise and consistent cutting.

– Environmental Considerations: Research into eco-friendly alternatives to traditional manufacturing processes.

By staying informed about the latest trends and innovations in this field, professionals can make better choices regarding the tools they use, ultimately leading to improved outcomes in their respective industries.

Request for Quotation

报错: 未找到这个表单