The Releated Products of Blade To Cut Quartz

Blade To Cut Quartz

Table of Contents

Choosing the Right Blade to Cut Quartz

When it comes to cutting quartz, selecting the appropriate blade can make all the difference. Quartz, known for its hardness and durability, requires specialized tools to ensure clean, precise cuts. A high-quality diamond blade designed specifically for cutting quartz is essential for any project, whether you’re a professional fabricator or a DIY enthusiast.

Diamond Blades for Cutting Quartz

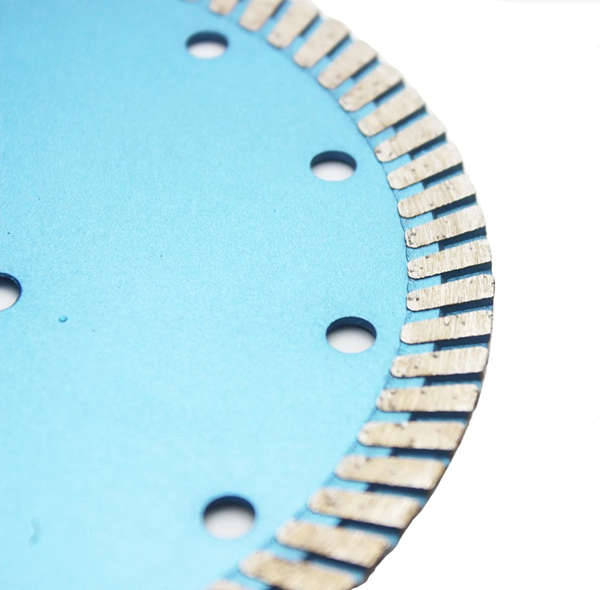

Diamond blades are the go-to choice when it comes to blade to cut quartz. These blades contain industrial diamonds embedded in the outer rim, which allows them to effectively cut through extremely hard materials like quartz. The diamond segments on these blades vary in size, concentration, and bond type, each suited for different applications and materials.

For cutting quartz, look for a blade with a higher concentration of diamonds and a softer bond. This combination provides both the strength needed to cut through the tough surface of quartz and the flexibility to handle the material without causing damage.

Factors to Consider When Selecting a Blade to Cut Quartz

Several factors play into choosing the best blade to cut quartz. Understanding these elements will help you select a blade that meets your specific needs:

1. Material Hardness: Quartz ranks high on the Mohs scale, making it one of the hardest materials used in construction and design. A blade with a hardness level that matches or exceeds the hardness of quartz is necessary.

2. Cutting Speed: Different blades have varying speeds at which they can cut through quartz. Faster cutting speeds can increase productivity but may also lead to more wear on the blade.

3. Cooling System: Effective cooling during the cutting process is crucial to prevent overheating, which can damage both the blade and the quartz. Water-fed systems are commonly used to keep the blade cool and reduce dust.

Maintenance of Blades Used to Cut Quartz

Proper maintenance of your blade to cut quartz is key to extending its lifespan and maintaining optimal performance. Regular cleaning and inspection can help identify issues early and prevent costly downtime.

After each use, rinse the blade thoroughly with water to remove any debris. Store the blade in a dry place away from extreme temperatures. Periodically inspect the blade for signs of wear such as chipping or uneven diamond distribution. Replacing worn blades promptly ensures consistent quality in your work.

Techniques for Using a Blade to Cut Quartz

Using the right techniques can significantly improve the efficiency and accuracy of cutting quartz. Here are some tips to consider:

– Start Slowly: Begin cutting at a slower speed to allow the blade to settle into the material. Gradually increase the speed as the cut progresses.

– Apply Steady Pressure: Maintain a consistent pressure throughout the cut. Excessive force can cause the blade to overheat or the quartz to crack.

– Use Lubrication: If possible, use a lubricant or water to keep the blade cool and reduce friction.

Benefits of Using the Correct Blade to Cut Quartz

Using the correct blade to cut quartz not only enhances the quality of the cut but also offers several other benefits:

– Increased Durability: High-quality blades last longer, reducing replacement costs over time.

– Improved Safety: Proper tools minimize the risk of accidents, ensuring a safer working environment.

– Better Finish: Clean, precise cuts result in a superior finish, enhancing the overall aesthetic appeal of the final product.

By considering these aspects, you can choose the most suitable blade to cut quartz, ensuring a successful outcome for your projects. Whether you’re working on a countertop installation or creating custom designs, investing in the right tools makes all the difference.

Request for Quotation

报错: 未找到这个表单