The Releated Products of Best Way To Cut Ceramic Tile With A Wet Saw

Best Way To Cut Ceramic Tile With A Wet Saw

Table of Contents

Best Way To Cut Ceramic Tile With A Wet Saw

Choosing The Right Wet Saw For Cutting Ceramic Tile

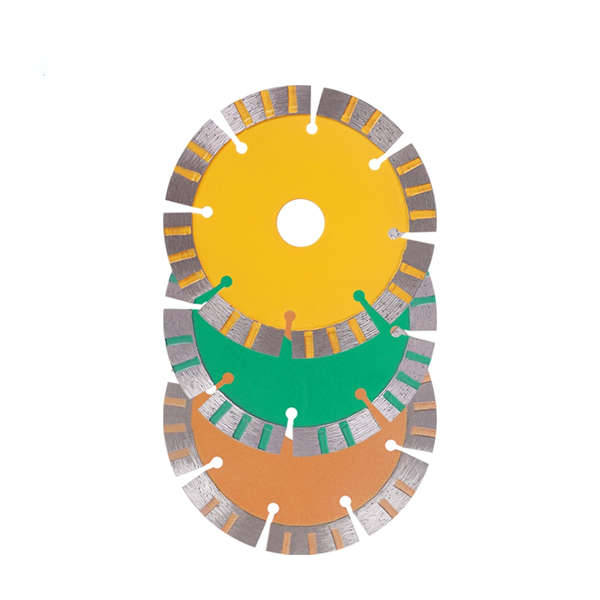

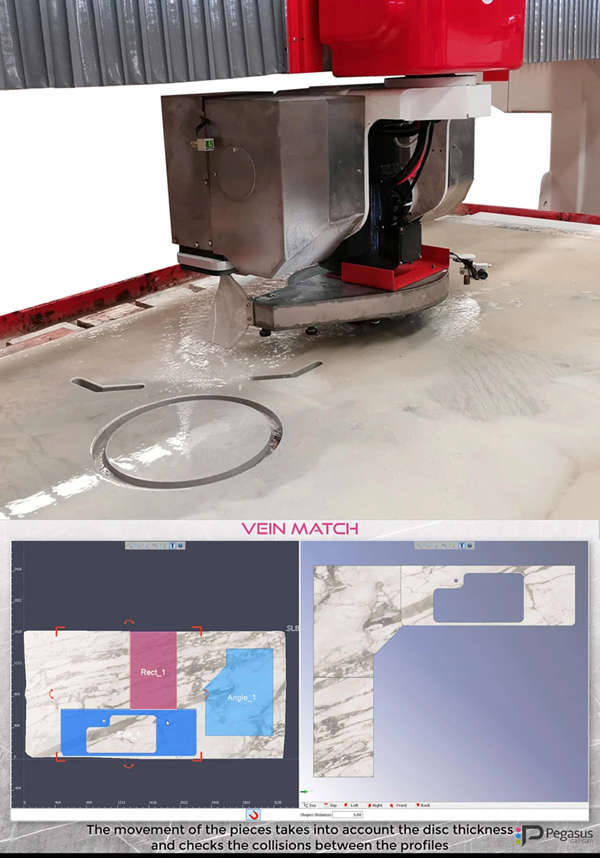

When it comes to cutting ceramic tile, having the right wet saw can make all the difference. A wet saw is specifically designed for masonry work, including cutting through tough materials like ceramic tiles. It uses a diamond blade that is continuously cooled by water during operation, which helps reduce friction and prevent overheating. This process ensures clean, precise cuts while minimizing dust and debris.

To select the best wet saw for your project, consider factors such as blade size, motor power, and portability. Larger blades allow for deeper cuts, making them ideal for thicker tiles or intricate patterns. More powerful motors provide smoother operation through denser materials. And if you’re working on multiple sites, a portable model might be more convenient.

Preparing Your Workspace For Cutting Ceramic Tile With A Wet Saw

Before you begin cutting ceramic tile with a wet saw, it’s crucial to prepare your workspace properly. First, ensure that the area is well-ventilated because even though wet saws minimize dust, some may still be present. Lay down plastic sheets or drop cloths to protect the floor from water splashes and tile fragments. Make sure the wet saw is placed on a stable, level surface to guarantee accurate cuts and prevent accidents.

It’s also important to have all necessary safety gear within reach, including goggles, gloves, and ear protection. Keeping these items nearby will help you maintain focus on your task without interruptions.

Tips For Accurate Cutting Of Ceramic Tile Using A Wet Saw

Accuracy is key when cutting ceramic tile with a wet saw. Start by marking your tile accurately using a pencil or chalk line. Use a square to ensure that your markings are straight and aligned correctly. Place the tile firmly onto the wet saw’s table, securing it with clamps if available.

When positioning the tile, keep in mind that you’ll need to adjust the blade guard to align with your cut line. Slowly guide the tile through the blade, applying steady pressure. Avoid rushing this process; taking your time will result in cleaner, more precise cuts.

Maintaining Your Wet Saw For Optimal Ceramic Tile Cutting Performance

Regular maintenance of your wet saw is essential for maintaining its performance and longevity, especially when used frequently for cutting ceramic tile. After each use, clean the saw thoroughly to remove any residual tile particles or slurry. Check the water flow to ensure it’s adequate for cooling the blade during operation.

Inspect the diamond blade periodically for signs of wear or damage. A dull or damaged blade can lead to rough edges and decreased cutting efficiency. If you notice any issues, replace the blade promptly to maintain high-quality results.

Safety Precautions When Cutting Ceramic Tile With A Wet Saw

Safety should always come first when operating a wet saw. Wear appropriate personal protective equipment (PPE) at all times. This includes safety glasses to shield your eyes from flying debris, hearing protection to guard against noise levels, and waterproof gloves to protect your hands from moisture and sharp edges.

Additionally, never leave the wet saw unattended while it’s running. Always turn off the machine and disconnect it from power sources before performing any maintenance or cleaning tasks. By following these guidelines, you can ensure a safer work environment and avoid potential hazards.

Frequently Asked Questions About Cutting Ceramic Tile With A Wet Saw

Q: Can I use a dry-cut blade on my wet saw?

A: While technically possible, it’s not recommended. Dry-cut blades are designed for use without water, and using them on a wet saw could lead to premature wear and tear of both the blade and the saw itself.

Q: How often should I replace the diamond blade?

A: The lifespan of a diamond blade depends on several factors, including usage frequency and the hardness of the materials being cut. As a general rule, inspect your blade regularly and replace it once it starts showing signs of wear, such as chipping or reduced cutting efficiency.

By following these tips and guidelines, you’ll be well-equipped to tackle any ceramic tile cutting project with confidence and precision. Remember, practice makes perfect, so don’t hesitate to experiment with different techniques until you find what works best for you.

Request for Quotation

报错: 未找到这个表单