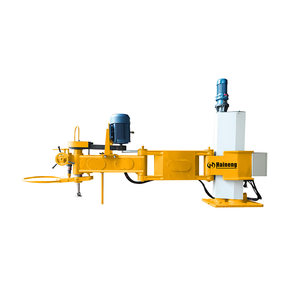

The Releated Products of Best Tile Saw For Cutting Rocks

Best Tile Saw For Cutting Rocks

Table of Contents

Best Tile Saw For Cutting Rocks: Unearthing the Ultimate Tools

Choosing the right tool for cutting rocks can make all the difference in achieving precision and efficiency. Whether you’re a professional mason or a DIY enthusiast, investing in a high-quality tile saw specifically designed for rock cutting is essential. In this guide, we’ll explore the best tile saws for cutting rocks, ensuring you find the perfect match for your projects.

Top Features of the Best Tile Saw For Cutting Rocks

When searching for the best tile saw for cutting rocks, several features stand out as must-haves. First, look for a powerful motor capable of handling dense materials like granite or slate. A diamond blade is another critical component, as it’s designed to cut through hard surfaces efficiently. Additionally, consider models with adjustable guides and fences, which enhance accuracy and control during the cutting process.

Reviews: Best Tile Saw For Cutting Rocks

To help you narrow down your choices, here are some of the top-rated tile saws specifically recommended for cutting rocks:

1. Wet Tile Saw with High-Torque Motor: This model boasts a robust motor that delivers exceptional torque, making it ideal for tackling tough jobs like cutting through thick slabs of rock. Its continuous water flow system keeps the blade cool and reduces dust, promoting cleaner cuts and longer blade life.

2. Portable Rock Cutting Saw with Adjustable Depth: Designed for versatility, this saw allows users to adjust the depth of cut, accommodating various thicknesses of stone. Its lightweight design and compact size make it easy to transport to different job sites, while still offering the power and precision needed for demanding tasks.

3. Professional Grade Rock Cutter with Dual Water Supply: Perfect for heavy-duty applications, this professional-grade saw comes equipped with dual water supply systems to ensure maximum cooling and dust suppression. It also features a large cutting capacity, enabling you to work on larger pieces of rock without compromising on performance.

Tips for Choosing the Best Tile Saw For Cutting Rocks

Selecting the best tile saw for cutting rocks involves considering factors beyond just price and brand reputation. Think about the types of rocks you’ll be working with most often—some saws perform better on softer stones, while others excel at cutting harder materials. Also, evaluate your workspace; if mobility is important, opt for a portable model. Lastly, don’t overlook safety features such as blade guards and emergency stop buttons—they’re crucial for protecting both the user and the tool.

Maintenance of Your Best Tile Saw For Cutting Rocks

Proper maintenance is key to extending the lifespan of your tile saw and maintaining its cutting efficiency. Regularly clean the saw after each use, paying special attention to remove any debris from around the blade and water pump. Lubricate moving parts as directed by the manufacturer’s guidelines. And, replace worn-out blades promptly to avoid damaging the motor or compromising safety.

Frequently Asked Questions About the Best Tile Saw For Cutting Rocks

Q: Can I use a regular tile saw to cut rocks?

A: While possible, using a specialized tile saw designed for cutting rocks will yield better results due to its enhanced power and durability.

Q: How do I choose the right diamond blade for my rock-cutting project?

A: Consider the hardness of the material you’re cutting and select a blade with an appropriate bond strength. Harder materials generally require softer bonds to expose new diamonds more quickly.

Q: Are wet tile saws necessary when cutting rocks?

A: Yes, especially for prolonged or frequent use. Wet cutting helps keep the blade cool, reduces friction, minimizes dust, and prolongs the life of your diamond blade.

By focusing on these aspects, you’ll be well-equipped to find the best tile saw for cutting rocks that meets your specific needs and budget. Remember, investing in quality tools today can save you time and effort in the long run, making every project smoother and more enjoyable.

Request for Quotation

报错: 未找到这个表单