The Releated Products of Best Diamond Wire Saw For Reinforced Concrete Cutting

Best Diamond Wire Saw For Reinforced Concrete Cutting

Table of Contents

Best Diamond Wire Saw For Reinforced Concrete Cutting

Diamond Wire Saws: The Ultimate Tool for Reinforced Concrete Cutting

When it comes to cutting through reinforced concrete, precision and efficiency are paramount. Traditional methods like using circular saws or blades can often be insufficient for larger projects. This is where diamond wire saws shine. Designed specifically for the task, these tools offer unparalleled control and speed when tackling dense materials. With their continuous loop of wire embedded with industrial-grade diamonds, they are capable of making clean cuts through even the toughest concrete structures.

Selecting the Best Diamond Wire Saw for Your Project

Choosing the right diamond wire saw is crucial for ensuring optimal performance during reinforced concrete cutting operations. Factors such as the size of the job, material hardness, and accessibility of the work area all play significant roles in determining which model will best suit your needs. For instance, if you’re working on a large-scale construction site, opting for a high-capacity saw with adjustable tension settings might be more beneficial compared to smaller, handheld versions better suited for detailed work.

Features to Consider When Buying a Diamond Wire Saw for Reinforced Concrete Cutting

Several key features define the effectiveness of a diamond wire saw designed for reinforced concrete cutting. Tension control systems allow users to maintain consistent pressure throughout the cut, ensuring straight lines and preventing deviations. Additionally, water cooling mechanisms not only prolong the life of the wire by reducing heat buildup but also help manage dust levels, creating a safer working environment. Another important aspect is the type of diamond segments used; softer bonds are ideal for harder materials like concrete, providing both durability and cutting efficiency.

Maintenance Tips for Extending the Life of Your Diamond Wire Saw Used in Reinforced Concrete Cutting

Proper maintenance is essential to keeping your diamond wire saw functioning at its best for reinforced concrete cutting tasks. Regular cleaning of the wire and guide wheels removes debris that could otherwise cause damage or reduce performance. Lubricating moving parts helps prevent wear and tear, while inspecting the wire regularly for signs of fraying ensures safety and reliability. Following manufacturer guidelines for storage and handling also plays a critical role in maintaining the longevity of your tool.

Advantages of Using Diamond Wire Saws Over Other Methods in Reinforced Concrete Cutting

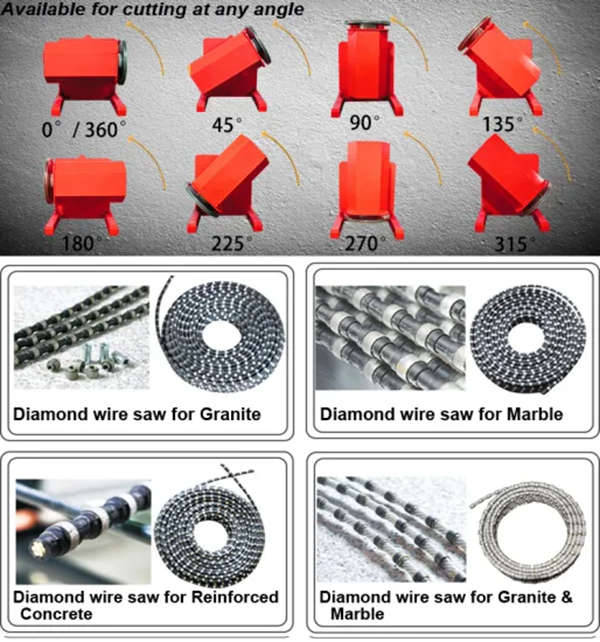

Compared to traditional blade-based systems, diamond wire saws offer several advantages when it comes to reinforced concrete cutting. Their ability to make precise cuts without generating excessive noise or vibration makes them particularly popular in urban areas where minimizing disruption is a priority. Furthermore, because they can operate at any angle and depth, they provide unparalleled flexibility, allowing contractors to tackle complex projects with ease. Lastly, the reduced risk of thermal cracking associated with diamond wire sawing means less post-cutting repair work, saving time and resources.

Top Brands and Models for Diamond Wire Saws Suitable for Reinforced Concrete Cutting

In the market for a reliable diamond wire saw for reinforced concrete cutting? Several leading manufacturers have established themselves as go-to sources for quality products. Husqvarna’s DXR 380, for example, combines power with portability, making it suitable for a wide range of applications. Similarly, HILTI’s DS-WZ 1000-X boasts advanced technology that enhances cutting speed and accuracy, perfect for demanding construction sites. Whether you’re looking for a heavy-duty machine or a compact solution, researching these top brands can help you find the ideal fit for your project requirements.

Request for Quotation

报错: 未找到这个表单