The Releated Products of Best Circular Saw Blade For Cutting Granite

Best Circular Saw Blade For Cutting Granite

Table of Contents

Best Circular Saw Blade For Cutting Granite: Precision, Power, and Performance

Choosing the Right Best Circular Saw Blade for Cutting Granite

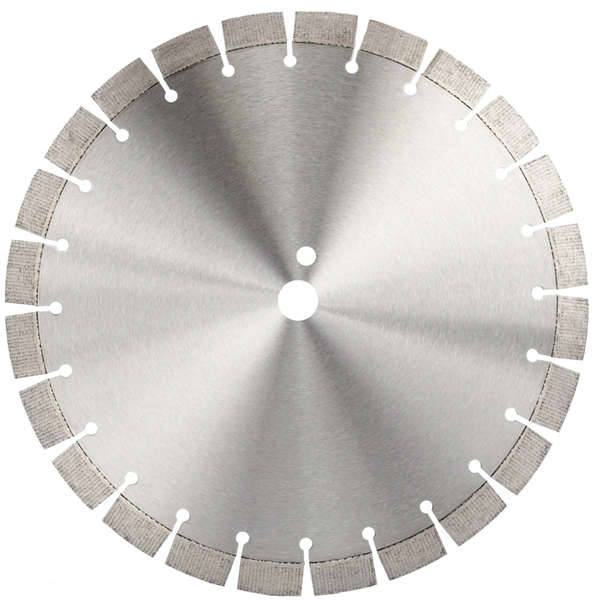

When it comes to cutting granite, choosing the best circular saw blade can make all the difference between a job well done and a frustrating experience. Granite is known for its hardness and durability, making it a popular choice for countertops, flooring, and various construction applications. However, these same qualities also present a significant challenge when it comes to cutting the material. A high-quality blade designed specifically for cutting granite will ensure clean cuts, increased efficiency, and a longer lifespan compared to general-purpose blades.

Features of the Best Circular Saw Blade for Cutting Granite

To tackle the tough task of cutting through granite, your blade needs to have specific features that enhance its performance and durability. Look for blades with diamond segments; these are essential for cutting through hard materials like granite. The diamond segments are made from synthetic diamonds embedded in a metal matrix, which allows them to cut through the stone effectively. Additionally, consider the blade’s diameter and the number of segments—it’s often recommended to use a larger blade with more segments for smoother cuts and better heat dissipation.

How to Use the Best Circular Saw Blade for Cutting Granite Safely

Safety is paramount when working with any power tool, especially when cutting granite with a circular saw. Always wear appropriate personal protective equipment (PPE), including safety glasses, dust masks, and hearing protection. Ensure that the work area is well-lit and free from obstructions. It’s also crucial to keep the blade properly lubricated during operation, as this helps reduce friction and overheating, extending the life of your blade and ensuring cleaner cuts.

Top Brands Offering the Best Circular Saw Blade for Cutting Granite

Several reputable brands manufacture high-quality circular saw blades tailored for cutting granite. Bosch, DeWalt, and Freud are among the leaders in the industry, offering a range of blades that cater to different cutting requirements. These brands typically use advanced manufacturing techniques and premium materials to produce blades that are durable, efficient, and capable of delivering precise cuts through granite.

Maintenance Tips for the Best Circular Saw Blade for Cutting Granite

Proper maintenance of your circular saw blade is key to maintaining its cutting efficiency and prolonging its lifespan. After each use, inspect the blade for any signs of damage or wear. Clean the blade thoroughly to remove any debris or residue that may have accumulated during cutting. Store the blade in a dry place away from extreme temperatures to prevent rust and corrosion. Regular maintenance will help ensure that your blade remains in top condition for future projects.

Choosing Between Wet and Dry Cutting with the Best Circular Saw Blade for Cutting Granite

When selecting a circular saw blade for cutting granite, you’ll need to decide whether to opt for wet or dry cutting. Wet cutting involves using water to cool the blade and reduce dust, while dry cutting does not require water. Both methods have their advantages and disadvantages. Wet cutting is generally considered safer and more effective for prolonged cutting sessions, as it reduces the risk of overheating and minimizes airborne dust particles. However, it requires a water supply and can be messier. Dry cutting is more convenient but may result in more dust and could potentially shorten the life of your blade if used extensively.

By considering these factors and choosing the best circular saw blade for cutting granite, you can ensure that your project proceeds smoothly and efficiently, with results that meet your standards of precision and quality.

Request for Quotation

报错: 未找到这个表单