The Releated Products of Automatic Marble Cutting Machine

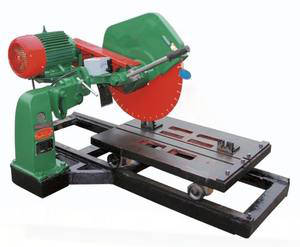

Automatic Marble Cutting Machine

Table of Contents

Enhancing Precision with Automatic Marble Cutting Machines

In the world of stone fabrication, precision and efficiency are paramount. This is where automatic marble cutting machines come into play, revolutionizing the way marbles are processed. These machines not only improve accuracy but also significantly enhance productivity, making them indispensable in modern workshops.

The Core Functionality of Automatic Marble Cutting Machines

An automatic marble cutting machine is designed to cut marble slabs with exceptional precision and speed. Equipped with advanced technology, these machines can handle complex designs and patterns with ease. They use computer-aided design (CAD) software for programming, ensuring that every cut is accurate to the finest detail. This level of control is particularly beneficial when working on intricate projects such as countertops, flooring, or sculptures.

Advantages of Using Automatic Marble Cutting Machines

The benefits of using an automatic marble cutting machine extend beyond just precision. These machines offer unparalleled speed, reducing production time while maintaining high standards of quality. Additionally, they require minimal human intervention once set up, allowing operators to focus on other tasks. Safety is another key advantage; automated systems reduce the risk of accidents commonly associated with manual cutting processes.

How Automatic Marble Cutting Machines Operate

Understanding how these machines operate provides insight into their capabilities. Typically, an automatic marble cutting machine consists of a gantry system that moves along rails, guiding a rotating blade powered by a motor. The blade is often diamond-tipped, capable of slicing through hard materials like marble effortlessly. Water jets are used to cool the blade and prevent overheating during operation. Operators input specific dimensions or patterns into the machine’s control panel, which translates these instructions into precise movements.

Maintenance and Care of Automatic Marble Cutting Machines

To ensure optimal performance and longevity, regular maintenance is crucial for automatic marble cutting machines. This includes cleaning the machine to remove dust and debris that could interfere with its operation. Lubrication of moving parts helps maintain smooth functionality. It’s also important to inspect the blade regularly for wear and tear, replacing it when necessary to avoid compromising the quality of cuts.

Applications of Automatic Marble Cutting Machines

From construction sites to art studios, the applications of automatic marble cutting machines are diverse. In construction, they are essential for creating custom marble pieces that fit perfectly into designated spaces. Artists and sculptors appreciate the machine’s ability to bring intricate designs to life, making it a valuable tool in their creative process. Furniture makers also rely on these machines to produce marble components that add elegance and durability to their products.

Future Innovations in Automatic Marble Cutting Technology

As technology advances, so too does the potential for innovation in automatic marble cutting machines. Future models may incorporate artificial intelligence (AI) to further streamline operations and improve customization options. Enhanced connectivity features could enable remote monitoring and control, offering greater flexibility for users. Additionally, advancements in material science might lead to the development of even more durable and efficient cutting blades.

By investing in an automatic marble cutting machine, businesses and artisans alike can elevate their craftsmanship while boosting productivity. These machines represent a significant leap forward in the field of stone processing, promising a future where creativity meets precision without compromise.

Request for Quotation

报错: 未找到这个表单