The Releated Products of Achilli Bridge Saw

Achilli Bridge Saw

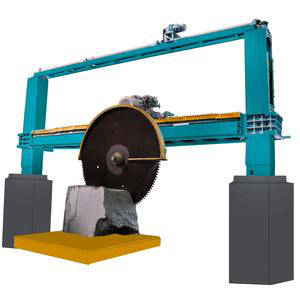

Achilli Bridge Saw: Precision and Power for Modern Stone Working

In the world of stone fabrication, precision and efficiency are paramount. The Achilli bridge saw stands out as a tool designed to meet these demands, offering unparalleled accuracy and speed. Whether you’re cutting marble, granite, or other natural stones, this machine is engineered to deliver exceptional results every time.

Achilli Bridge Saw Features: Enhancing Productivity

When it comes to choosing the right equipment for your workshop, the features of a Achilli bridge saw can significantly impact productivity and quality. These machines come equipped with advanced technologies such as digital controls and automatic functions that simplify the cutting process. High-torque motors ensure powerful cuts through even the hardest materials, while adjustable tables provide flexibility in handling different sizes and shapes of stone slabs.

Benefits of Using an Achilli Bridge Saw

Investing in a Achilli bridge saw brings numerous benefits to any stone fabrication business. Not only does it increase production rates due to its fast cutting speeds, but it also enhances the safety of operations by reducing manual handling of heavy materials. Additionally, the durability and robust construction of these saws mean they require minimal maintenance, ensuring long-term reliability and cost-effectiveness.

How Does an Achilli Bridge Saw Operate?

Understanding how a Achilli bridge saw operates can help operators maximize its potential. Typically, these machines utilize a gantry-style design where the cutting head moves along rails above the workpiece. This design allows for precise linear cuts without the need for constant repositioning of the material. Operators can input specific measurements into the control panel, guiding the blade accurately through the stone with minimal effort.

Maintenance Tips for Your Achilli Bridge Saw

To keep your Achilli bridge saw running smoothly and extend its lifespan, regular maintenance is essential. This includes cleaning the machine after each use, lubricating moving parts, and checking for wear on components like belts and bearings. Following the manufacturer’s guidelines for service intervals will help prevent unexpected downtime and maintain optimal performance levels.

Choosing the Right Achilli Bridge Saw for Your Needs

With various models available, selecting the appropriate Achilli bridge saw depends on factors such as the volume of work, types of materials being cut, and specific requirements of your projects. For smaller operations focusing on custom work, a compact model might suffice. Larger businesses processing high volumes of stone may benefit more from industrial-grade versions with enhanced capabilities.

Conclusion: Elevating Your Stone Fabrication Business with Achilli

By incorporating a Achilli bridge saw into your workflow, you’re investing in technology that supports growth and innovation within your business. From enhancing operational efficiency to improving product quality, these machines offer a competitive edge in today’s demanding market. As you explore different models and configurations, consider how each feature aligns with your goals to make the best choice for your unique situation.

The Achilli bridge saw represents more than just a piece of equipment; it’s a partner in achieving excellence in stone fabrication. Its combination of cutting-edge technology, durable build quality, and user-friendly design makes it an indispensable asset for professionals committed to delivering top-notch craftsmanship.

Request for Quotation

报错: 未找到这个表单