The Releated Products of Accessories Bridge Saw Ceramic

Accessories Bridge Saw Ceramic

Table of Contents

Accessories Bridge Saw Ceramic: Enhancing Precision and Efficiency

In the dynamic world of stone fabrication, precision and efficiency are paramount. One tool that has significantly revolutionized this industry is the bridge saw, particularly when paired with specialized accessories designed for cutting ceramic materials. These accessories bridge saw ceramic not only improve the quality of cuts but also enhance productivity, making them indispensable for both professionals and DIY enthusiasts.

Choosing the Right Accessories Bridge Saw Ceramic

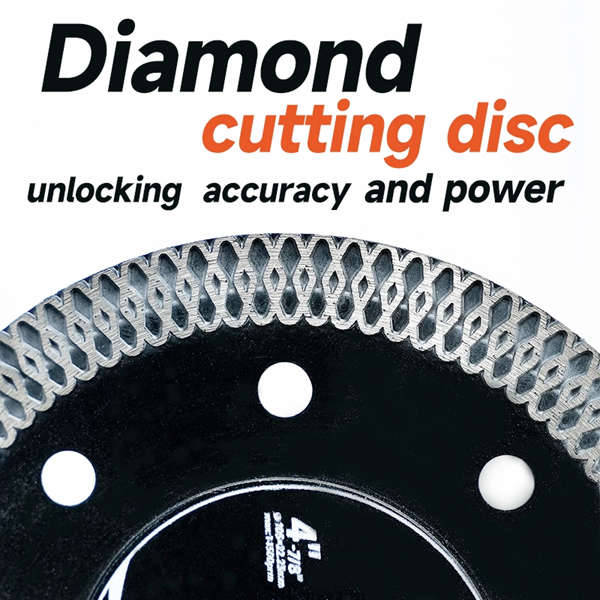

Selecting the appropriate accessories bridge saw ceramic can make a substantial difference in your project’s outcome. When shopping for these tools, consider factors such as blade diameter, material type, and tooth configuration. For ceramics, diamond blades are preferred due to their ability to cut through hard surfaces smoothly without chipping. Ensure the blade fits your saw model and that it’s capable of producing clean, precise cuts.

Maintaining Your Accessories Bridge Saw Ceramic

To keep your accessories bridge saw ceramic performing at their best, regular maintenance is crucial. This includes cleaning the blade after each use to remove any debris or residue that could affect future cuts. Additionally, inspecting the blade for wear and tear periodically helps prevent accidents and ensures consistent performance. Lubricating moving parts can also extend the life of your equipment, making it a worthwhile investment.

Safety Tips for Using Accessories Bridge Saw Ceramic

Safety should always come first when operating any power tool, including those equipped with accessories bridge saw ceramic. Always wear protective gear such as safety glasses, gloves, and ear protection. Ensure the work area is well-lit and free from clutter. Follow manufacturer guidelines for setup and operation, and never force the blade through material; let the saw do the work to avoid kickback or other hazards.

Enhancing Performance with Accessories Bridge Saw Ceramic

The right set of accessories bridge saw ceramic can dramatically improve the performance of your bridge saw. Consider investing in water cooling systems to maintain blade temperature and reduce dust during cutting. Adjustable fences and clamps provide better control over the material being cut, ensuring straight lines and accurate angles. Upgrading to high-quality components can significantly impact your overall workflow and final product quality.

Troubleshooting Common Issues with Accessories Bridge Saw Ceramic

Despite proper care and maintenance, issues may arise when using accessories bridge saw ceramic. Common problems like wobbling blades or rough edges can often be resolved by tightening loose parts or replacing worn-out components. If you experience excessive vibration or noise, check the alignment of your blade and ensure it’s properly balanced. Consulting the user manual or contacting the manufacturer for advice on specific issues can also be beneficial.

Expanding Capabilities Through Accessories Bridge Saw Ceramic

As you become more experienced with your bridge saw and its accessories bridge saw ceramic, consider expanding your capabilities by exploring new applications. Specialized blades allow for cutting different types of materials, while additional attachments can help with tasks like edge profiling or hole drilling. This versatility makes your investment even more valuable, allowing you to tackle a wider range of projects with confidence and precision.

By focusing on choosing the right accessories bridge saw ceramic, maintaining them properly, prioritizing safety, enhancing performance, troubleshooting common issues, and exploring expanded capabilities, you can maximize the potential of your bridge saw. Whether you’re a seasoned professional or just starting out, these tips will help ensure that your projects are completed efficiently and to the highest standard possible.

Request for Quotation

报错: 未找到这个表单