The Releated Products of 52 Tile Cutter

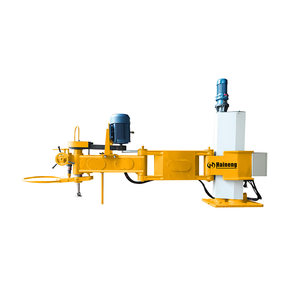

52 Tile Cutter

Table of Contents

The Precision and Power of the 52-Inch Tile Cutter: A Comprehensive Review

When it comes to cutting tiles for your home or commercial projects, having the right tool can make all the difference. The 52-inch tile cutter stands out as a versatile and powerful option for professionals and DIY enthusiasts alike. This article will explore the key features, benefits, and considerations when using a 52 tile cutter, ensuring that you make an informed decision.

52 Tile Cutter: Enhancing Efficiency and Accuracy

One of the primary advantages of opting for a 52 tile cutter over smaller models is its ability to handle larger tiles with ease. Whether you’re working with porcelain, ceramic, or stone, this size provides ample space to maneuver, reducing the need for multiple cuts on large slabs. The extended cutting bed ensures stability, promoting straighter lines and cleaner edges, which are crucial for achieving a professional finish.

Understanding the Mechanics of a 52 Tile Cutter

To fully appreciate the capabilities of a 52 tile cutter, it’s important to understand its core components. Most models feature a robust motor capable of delivering high-speed rotations, essential for slicing through dense materials without chipping or cracking. The rail system, another critical aspect, must be precisely engineered to support smooth, guided movements. High-quality bearings and a durable frame contribute to the overall longevity and reliability of these machines.

Choosing the Right 52 Tile Cutter for Your Needs

Not all 52 tile cutters are created equal, and choosing the best one depends largely on your specific requirements. Factors such as the type of tiles you’ll be working with, the frequency of use, and your budget all play significant roles. For instance, if you anticipate cutting a lot of granite or other hard stones, look for a model equipped with a diamond blade designed for tough materials. Additionally, consider ergonomic features like adjustable handles and lightweight designs for more comfortable operation during extended periods.

Maintenance Tips for Your 52 Tile Cutter

Proper maintenance is key to extending the life of your 52 tile cutter and maintaining optimal performance. Regularly cleaning the machine, especially the cutting area, helps prevent buildup that could affect accuracy. Lubricating moving parts reduces wear and tear, while inspecting and replacing worn blades ensures safe and efficient operation. Following the manufacturer’s guidelines for care and storage can significantly enhance the durability of your equipment.

Safety Considerations When Using a 52 Tile Cutter

Safety should always be a top priority when operating any power tool, including a 52 tile cutter. Always wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and dust masks. Ensure that the workspace is well-lit and free from clutter to avoid accidents. Familiarize yourself with the machine’s safety features, like emergency stop buttons and guards, and never bypass them. Training and adherence to best practices are vital for preventing injuries.

Exploring Advanced Features in Modern 52 Tile Cutters

As technology advances, so do the features available in 52 tile cutters. Some models now offer digital readouts for precise measurements, variable speed controls for adapting to different materials, and even built-in vacuum systems to manage dust. These innovations not only improve efficiency but also make the cutting process safer and more manageable. Researching the latest models can help you find the perfect balance between functionality and cost-effectiveness.

In conclusion, a 52 tile cutter represents a significant investment for those involved in tiling projects. By considering factors like efficiency, mechanics, suitability for your needs, maintenance requirements, safety protocols, and advanced features, you can select a machine that meets your expectations and delivers exceptional results. Whether you’re a seasoned professional or a beginner, the right 52 tile cutter can transform your work, enhancing both productivity and quality.

Request for Quotation

报错: 未找到这个表单