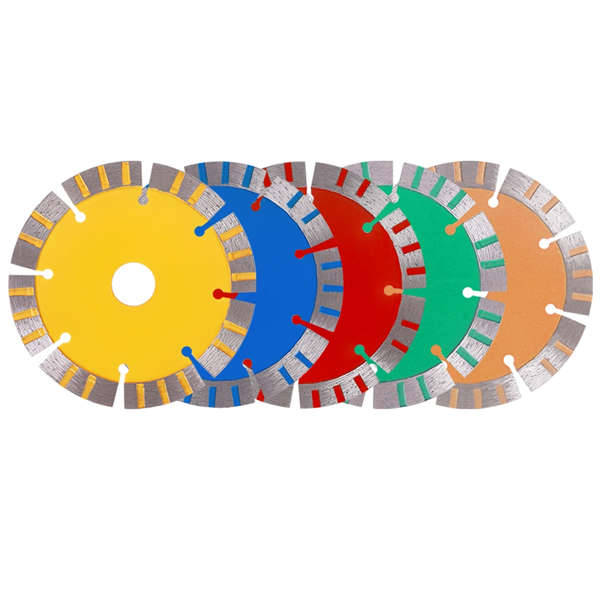

The Releated Products of 4 1 2 Hole Saw Ceramic

4 1 2 Hole Saw Ceramic

Understanding the 4 1 2 Hole Saw Ceramic: Precision Cutting for Ceramics

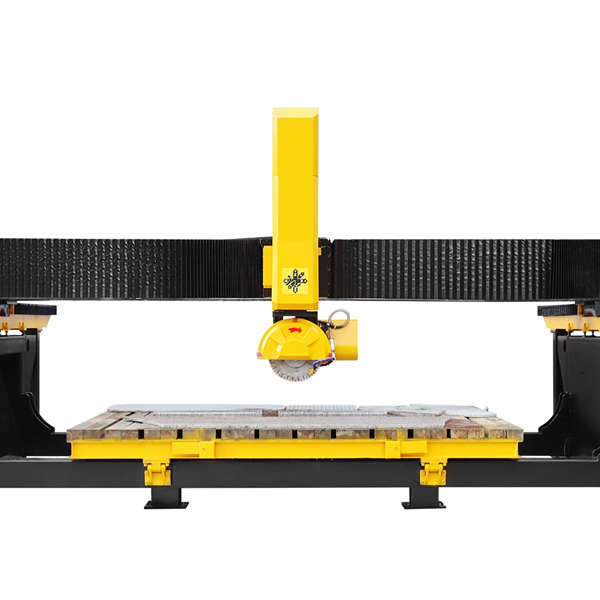

When it comes to cutting through ceramics, precision and durability are paramount. This is where the 4 1 2 hole saw ceramic shines, offering unparalleled performance and reliability. Whether you’re a professional contractor or a DIY enthusiast, understanding the features and benefits of this specialized tool can make all the difference in your projects.

Choosing the Right 4 1 2 Hole Saw Ceramic for Your Project

Selecting the appropriate 4 1 2 hole saw ceramic is crucial for achieving clean, precise cuts. Consider the material’s thickness and hardness when choosing a hole saw. For instance, a denser ceramic might require a more robust and durable 4 1 2 hole saw ceramic. Always opt for high-quality tools made from materials such as diamond-impregnated steel, which are specifically designed to cut through ceramics without chipping or cracking.

Benefits of Using a 4 1 2 Hole Saw Ceramic

The 4 1 2 hole saw ceramic offers several advantages over traditional cutting methods. Firstly, its design ensures minimal wear and tear on the tool itself, extending its lifespan. Secondly, the 4 1 2 hole saw ceramic produces cleaner edges, reducing the need for extensive post-cutting finishing work. Lastly, using a 4 1 2 hole saw ceramic enhances safety by minimizing the risk of breakage during the cutting process.

Maintaining Your 4 1 2 Hole Saw Ceramic

Proper maintenance is key to ensuring the longevity and efficiency of your 4 1 2 hole saw ceramic. After each use, clean the tool thoroughly to remove any debris or residue. Storing the 4 1 2 hole saw ceramic in a dry, protected environment will also help prevent rust and corrosion. Regularly inspect the teeth and cutting edge for signs of damage or wear, replacing the tool if necessary to maintain optimal performance.

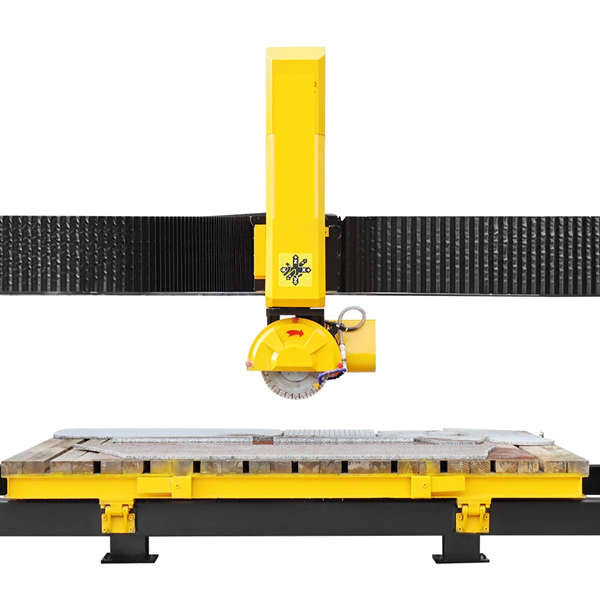

Techniques for Efficient Cutting with a 4 1 2 Hole Saw Ceramic

Using the right techniques can significantly improve the effectiveness of your 4 1 2 hole saw ceramic. Start by marking the cutting area clearly on the ceramic surface. Apply steady, even pressure while operating the drill, allowing the 4 1 2 hole saw ceramic to do most of the work. It’s also beneficial to use a lubricant, such as water or a specialized cutting fluid, to reduce friction and heat buildup, thereby prolonging the life of your 4 1 2 hole saw ceramic.

Troubleshooting Common Issues with Your 4 1 2 Hole Saw Ceramic

Even with proper use and maintenance, issues may arise when working with a 4 1 2 hole saw ceramic. If you encounter difficulty cutting through the material or notice excessive wear on the tool, it could be due to using too much force or an incorrect cutting technique. Adjust your approach and, if necessary, consult the manufacturer’s guidelines for specific troubleshooting tips related to your 4 1 2 hole saw ceramic model.

Conclusion

In conclusion, the 4 1 2 hole saw ceramic is an indispensable tool for anyone working with ceramics. Its unique design and specialized features make it ideal for achieving precise, clean cuts with minimal effort. By choosing the right tool, employing effective cutting techniques, and maintaining your 4 1 2 hole saw ceramic properly, you can ensure a long-lasting, efficient cutting experience every time.

Request for Quotation

报错: 未找到这个表单