The Releated Products of 22kw Diamond Wire Saw Machine

22kw Diamond Wire Saw Machine

Table of Contents

Understanding the 22kw Diamond Wire Saw Machine: A Comprehensive Guide

In the realm of construction and mining, precision and efficiency are paramount. This is where the 22kw Diamond Wire Saw Machine shines, offering unparalleled cutting capabilities for a wide range of materials. Designed to tackle the toughest jobs with ease, this machine is a testament to modern engineering. Let’s delve into what makes it stand out and explore its applications, benefits, and operational nuances.

Advantages of Using a 22kw Diamond Wire Saw Machine

When it comes to cutting through hard materials like reinforced concrete, granite, or marble, the 22kw Diamond Wire Saw Machine offers several advantages over traditional methods. Its high-power motor ensures fast, clean cuts with minimal vibration, reducing the risk of damage to surrounding structures. Additionally, the machine’s ability to make precise cuts without producing excessive noise or dust makes it ideal for use in residential areas or enclosed spaces.

Applications of the 22kw Diamond Wire Saw Machine

The versatility of the 22kw Diamond Wire Saw Machine is evident in its diverse applications across various industries. In construction, it is used for demolition projects, bridge repairs, and cutting slabs. For mining operations, it excels in extracting stone blocks from quarries with minimal waste. Moreover, its adaptability extends to specialized tasks such as creating openings in existing structures or performing detailed sculptural work.

Technical Specifications of the 22kw Diamond Wire Saw Machine

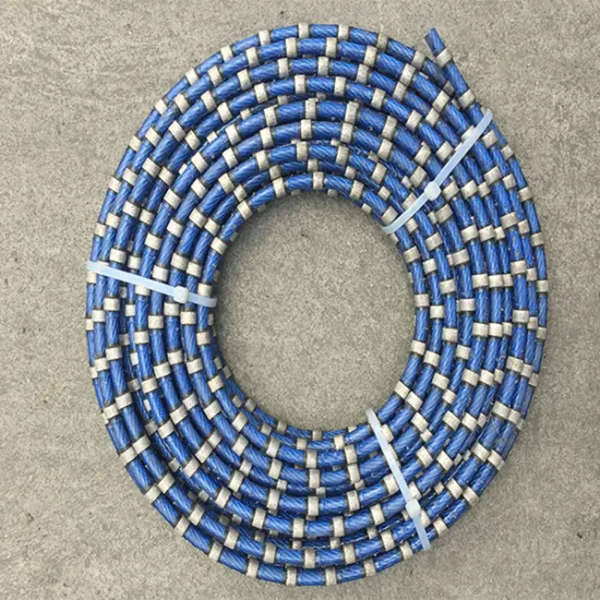

To fully appreciate the capabilities of the 22kw Diamond Wire Saw Machine, one must consider its technical specifications. Equipped with a powerful 22-kilowatt motor, it can achieve cutting depths up to 2 meters, depending on the material and wire configuration. The machine supports both wet and dry cutting, allowing operators to choose the method best suited for their specific needs. Furthermore, its modular design facilitates easy maintenance and upgrades.

Operating the 22kw Diamond Wire Saw Machine

Proper operation of the 22kw Diamond Wire Saw Machine requires adherence to safety protocols and understanding of its control systems. Operators must be trained to adjust tension settings according to the hardness of the material being cut. Regular inspections and timely replacement of worn parts are crucial for maintaining optimal performance and extending the machine’s lifespan. Training programs often include hands-on experience to ensure familiarity with all aspects of the machine’s functionality.

Maintenance Requirements for the 22kw Diamond Wire Saw Machine

Like any heavy-duty machinery, the 22kw Diamond Wire Saw Machine demands regular maintenance to keep it running smoothly. This includes checking and lubricating moving parts, inspecting the wire for wear, and ensuring that all electrical connections are secure. Preventive maintenance schedules help in identifying potential issues early, preventing costly downtime during critical operations.

Environmental Impact of the 22kw Diamond Wire Saw Machine

Given its power and efficiency, the 22kw Diamond Wire Saw Machine plays a significant role in reducing the environmental impact of construction and mining activities. By minimizing material waste and improving operational speeds, it contributes to lower carbon footprints associated with these industries. Additionally, advancements in diamond wire technology have led to increased durability and recyclability of components, further enhancing its eco-friendly credentials.

Understanding the intricacies of the 22kw Diamond Wire Saw Machine reveals why it has become an indispensable tool across multiple sectors. From its robust design to innovative features, this machine continues to set new standards in cutting performance and sustainability.

Request for Quotation

报错: 未找到这个表单