The Releated Products of 2 Hole Saw For Ceramic Tile

2 Hole Saw For Ceramic Tile

Table of Contents

2 Hole Saw for Ceramic Tile: Precision Cutting Made Easy

When it comes to home improvement projects, cutting ceramic tiles can be a challenging task. Whether you’re installing a new bathroom floor or renovating your kitchen backsplash, having the right tools is crucial. One such tool that stands out for its precision and ease of use is the 2 hole saw for ceramic tile. This specialized piece of equipment allows DIY enthusiasts and professionals alike to create clean, accurate holes in ceramic tiles with minimal effort.

Selecting the Right 2 Hole Saw for Ceramic Tile

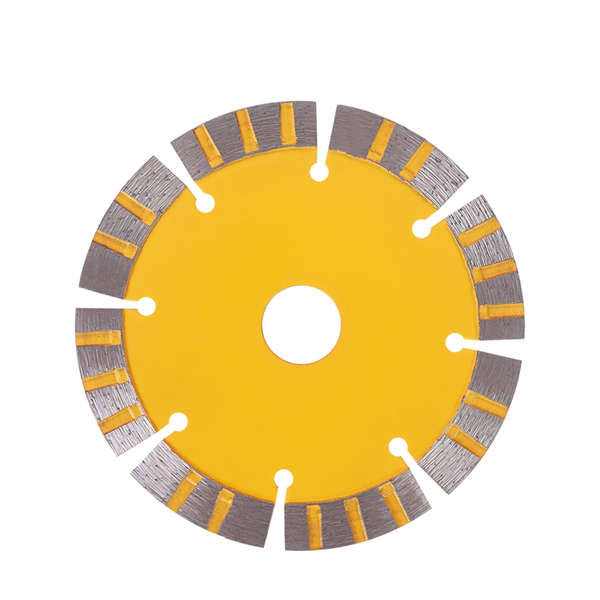

Choosing the 2 hole saw for ceramic tile that best suits your project requires considering several factors. Diameter size, material quality, and compatibility with your drill are all important considerations. For instance, if you need to install fixtures or pipes through tiles, a larger diameter might be necessary. On the other hand, smaller diameters are ideal for electrical outlets and light switches. Always ensure that the 2 hole saw for ceramic tile you choose is made from durable materials like diamond or tungsten carbide, which can withstand the hardness of ceramics without chipping or breaking the tile.

Preparing to Use Your 2 Hole Saw for Ceramic Tile

Before you begin drilling, preparation is key to achieving successful results with your 2 hole saw for ceramic tile. Start by marking the exact spot where you want to make the hole using a pencil or marker. Place masking tape over this area to prevent the tile from cracking under pressure. It’s also advisable to wet the drill bit periodically when using a 2 hole saw for ceramic tile, as this helps reduce friction and keeps the tile cool during the cutting process.

Techniques for Using a 2 Hole Saw on Ceramic Tile

Using a 2 hole saw for ceramic tile efficiently involves employing the correct technique. Begin by applying gentle pressure as you start drilling; this helps create a pilot hole that guides the bit more accurately. Increase the speed gradually once the bit starts penetrating the surface. Remember to maintain steady pressure throughout the drilling process to avoid slippage or uneven cuts. If you encounter resistance, stop and adjust your approach to prevent damaging the tile.

Troubleshooting Common Issues with 2 Hole Saws for Ceramic Tile

Even experienced users may face challenges when working with 2 hole saws for ceramic tile. Common issues include overheating, chipping around the edges, or the drill bit getting stuck. To address these problems, ensure that you’re using water for cooling purposes and that the bit is sharp enough to cut through the tile smoothly. If chipping occurs, consider starting with a smaller pilot hole before switching to the 2 hole saw for ceramic tile. For stuck bits, try tapping gently around the perimeter with a hammer and punch to loosen it.

Maintaining Your 2 Hole Saw for Ceramic Tile

Proper maintenance extends the life of your 2 hole saw for ceramic tile and ensures consistent performance over time. After each use, clean the bit thoroughly to remove any debris or residue. Store it in a dry place away from corrosive substances. Periodically inspect the condition of the diamond or carbide coating; dull or worn-out bits should be replaced immediately to maintain cutting efficiency. By following these simple steps, you can keep your 2 hole saw for ceramic tile in top condition, ready for any future projects.

In conclusion, investing in a high-quality 2 hole saw for ceramic tile is essential for anyone looking to achieve professional-looking results in their tiling projects. With the right selection, preparation, techniques, and care, you’ll be able to tackle even the most demanding tasks with confidence and precision.

Request for Quotation

报错: 未找到这个表单